Sealing Solution- Unveiling the Strength of Spiral Wound Gasket Materials

In the realm of industrial sealing solutions, spiral wound gaskets represent a pinnacle of engineering excellence. These gaskets are meticulously designed to provide superior sealing performance in the most demanding environments. The key to their effectiveness lies in the materials used in their construction. This article explores the various gasket materials that comprise spiral wound gaskets, highlighting their unique properties and the critical role they play in ensuring reliability and efficiency across diverse industrial applications.

Understanding Spiral Wound Gaskets:

Spiral wound gaskets are constructed by spirally winding a combination of metallic and filler materials. This design allows them to accommodate varying pressure and temperature conditions, making them ideal for applications in industries such as oil and gas, chemical processing, power generation, and more. The choice of materials used in spiral wound gaskets is crucial to their performance and durability.

Key Materials Used in Spiral Wound Gaskets:

Metallic Components:

- Stainless Steel: One of the most commonly used metals in spiral wound gaskets, stainless steel offers excellent resistance to corrosion and oxidation. Types 304, 316, and 321 stainless steels are popular choices, each providing different levels of chemical resistance and temperature tolerance.

- Monel: An alloy of nickel and copper, Monel is highly resistant to acids, alkalis, and seawater, making it suitable for marine and chemical processing applications.

- Inconel: This nickel-chromium alloy is known for its exceptional strength and oxidation resistance at high temperatures, making it ideal for applications involving extreme heat.

Filler Materials:

- Flexible Graphite: Renowned for its excellent thermal conductivity and chemical resistance, flexible graphite is a preferred filler material for high-temperature and high-pressure applications. It maintains its sealing properties even under severe conditions.

- PTFE (Polytetrafluoroethylene): PTFE offers outstanding chemical resistance and low friction properties, making it suitable for applications involving aggressive chemicals and where contamination must be minimized.

- Mica: Used primarily in applications requiring high temperature resistance, mica fillers can withstand temperatures up to 1000°C, making them ideal for use in power plants and other high-heat environments.

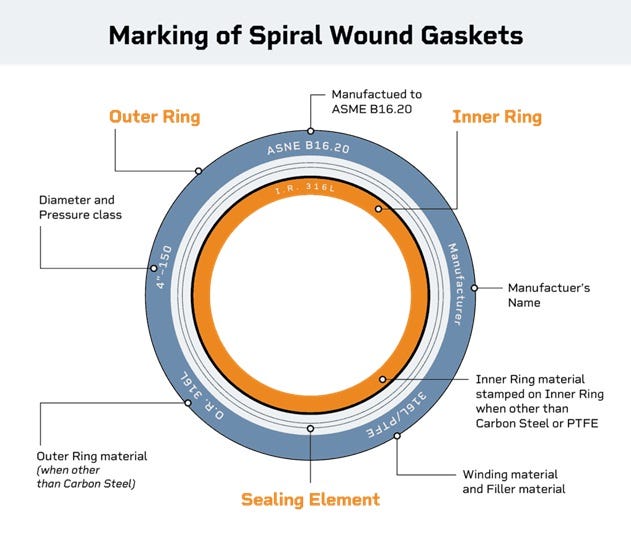

Outer and Inner Rings:

- The outer and inner rings of spiral wound gaskets are typically made from carbon steel or stainless steel. These rings provide structural integrity, centering the gasket within the flange and preventing blowout under pressure. The choice of ring material depends on the specific requirements of the application, such as resistance to corrosion or thermal expansion.

Advantages of Spiral Wound Gasket Materials:

High-Temperature and Pressure Resistance:

- The combination of metallic and filler materials in spiral wound gaskets allows them to perform reliably under extreme conditions, withstanding high temperatures and pressures without losing their sealing integrity.

Chemical Compatibility:

- The use of materials such as stainless steel, Monel, and PTFE ensures that spiral wound gaskets are resistant to a wide range of chemicals, making them suitable for applications in harsh chemical environments.

Versatility:

- Spiral wound gaskets can be customized to meet specific application requirements by selecting appropriate combinations of metallic and filler materials. This versatility makes them suitable for a broad range of industries and operational conditions.

Longevity and Reliability:

The robust construction and high-quality materials used in spiral wound gaskets contribute to their long service life and reliability, reducing the need for frequent maintenance and replacement.

Conclusion:

The effectiveness of spiral wound gaskets in providing reliable sealing solutions is a testament to the ingenuity of their design and the quality of materials used in their construction. By combining various metallic and filler materials, these gaskets offer unparalleled performance in demanding industrial applications. As industries continue to evolve and face new challenges, the adaptability and resilience of spiral wound gasket materials ensure that they remain a cornerstone of industrial sealing technology, safeguarding the integrity and efficiency of critical systems worldwide.

Original Source: Spiral Wound Gasket Material

Comments

Post a Comment